Technology Overview

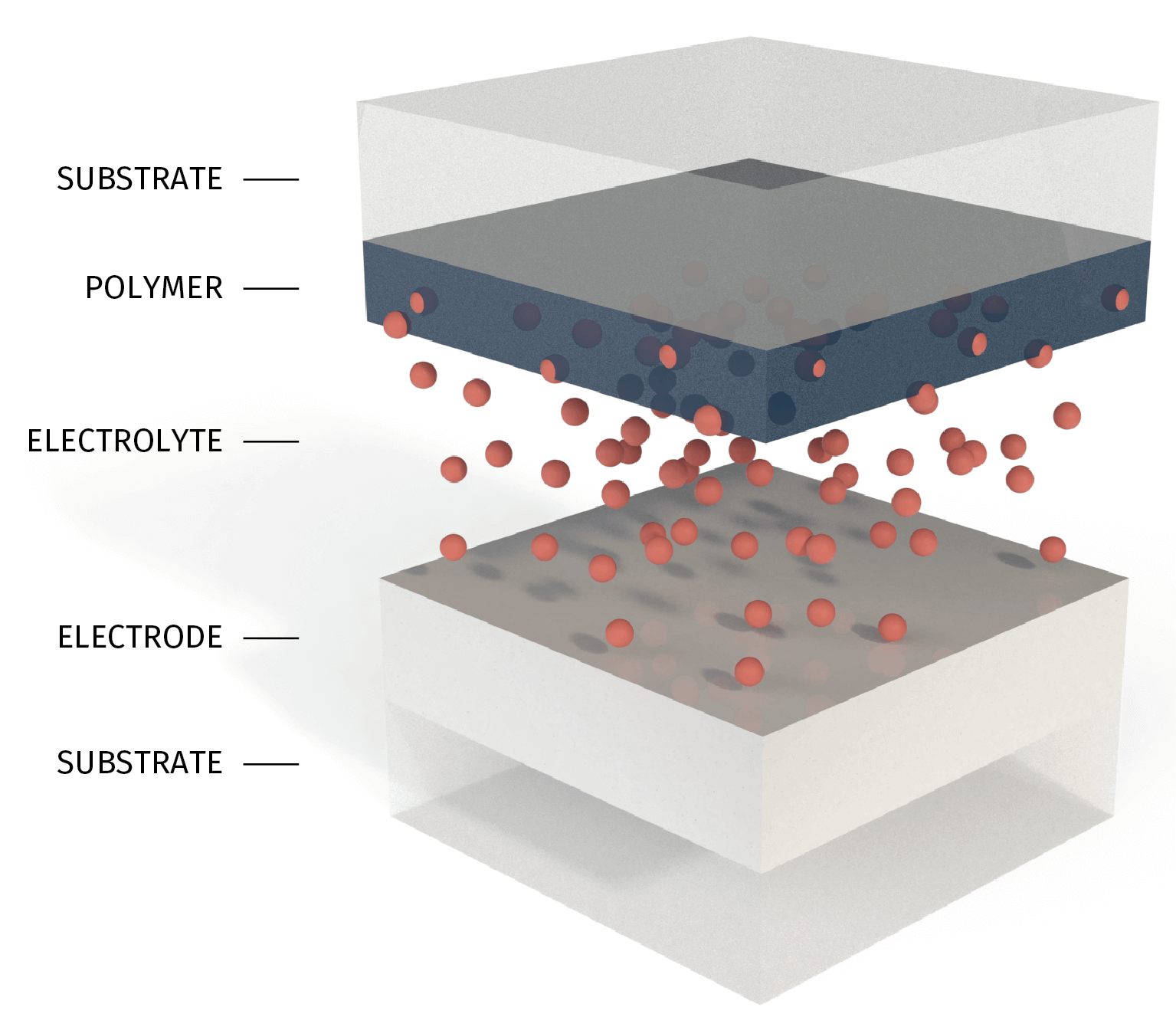

The Rdot Display is an electrochromic display. It is categorized as a reflective display - meaning that it reflects ambient light instead of using a backlight. All layers are screen printed on a plastic substrate.

The display stack consists of organic layers including a plastic substrate, an electrochromic material, an electrolyte, and an electrode for each segment. Additional layers such as graphical overlays, circuits, and barrier layers may be added if required.

Ultra-Low Energy Consumption

The Rdot Display has the lowest energy consumption on the market for many use-cases. For static usage (when the display maintains the same image) the display consumes a maximum of 0,28µW per cm2 segment area. For dynamic usage, the power consumption depends on the number of display updates per day according to the formula below.

Power Calculation

Scenario: The display content is allowed to fade out

For various applications, the display is needed only when the user is interacting with the device and altering the information that should be displayed. The illustration below shows a scenario where the screen is activated when a number changes. A voltage is applied for a brief period to update the display information. Once updated, the voltage is removed to let the display information fade out over the next few hours. This display driving scenario creates an extremely low-powered solution. See the table for example specifications and energy consumption.

| Example Energy Consumption | ||

|---|---|---|

| Average segment area | 0.1 square centimeters | |

| Number of segments | 21 (3 x 7 segment) | |

| Total display segments area | 2.1 square centimeters | |

| Driving voltage | 3 V | |

| Full switch energy for all segments | 1.26 mJ | |

| #switches during product lifetime | 10 000 | |

| Required battery capacity | 1.2 mAh | |

Scenario: the display is always on and readable

Several applications require that the user can read the display at any time. The display memory is utilized to optimize the driving in order to achieve as low energy consumption as possible. After a full switch, e.g., when the display information is updated, the display driver can go to deep sleep for approximately 15 minutes. After the display memory time of 15 minutes, a small refresh pulse is needed to maintain full contrast. The refresh pulsing will run continuously every 15 minutes to keep the display powered continuously. A refresh pulse typically consumes 25% of the energy of a full segment switch (entirely off to on or vice versa). See table and the illustrations for example specifications.

| Example Energy Consumption | ||

|---|---|---|

| Average segment area | 0.1 square centimeters | |

| Number of segments | 21 (3 x 7 segment) | |

| Total display segments area | 2.1 square centimeters | |

| Driving voltage | 3 V | |

| Full switch energy for all segments | 1.26 mJ | |

| Display active lifetime | 5 years | |

| Refresh pulse frequency | Every 15th minutes | |

| #switches during product lifetime | 10 000 | |

| Refresh pulse energy (%of full switch energy) | 25% | |

| Required battery capacity | 6 mAh | |

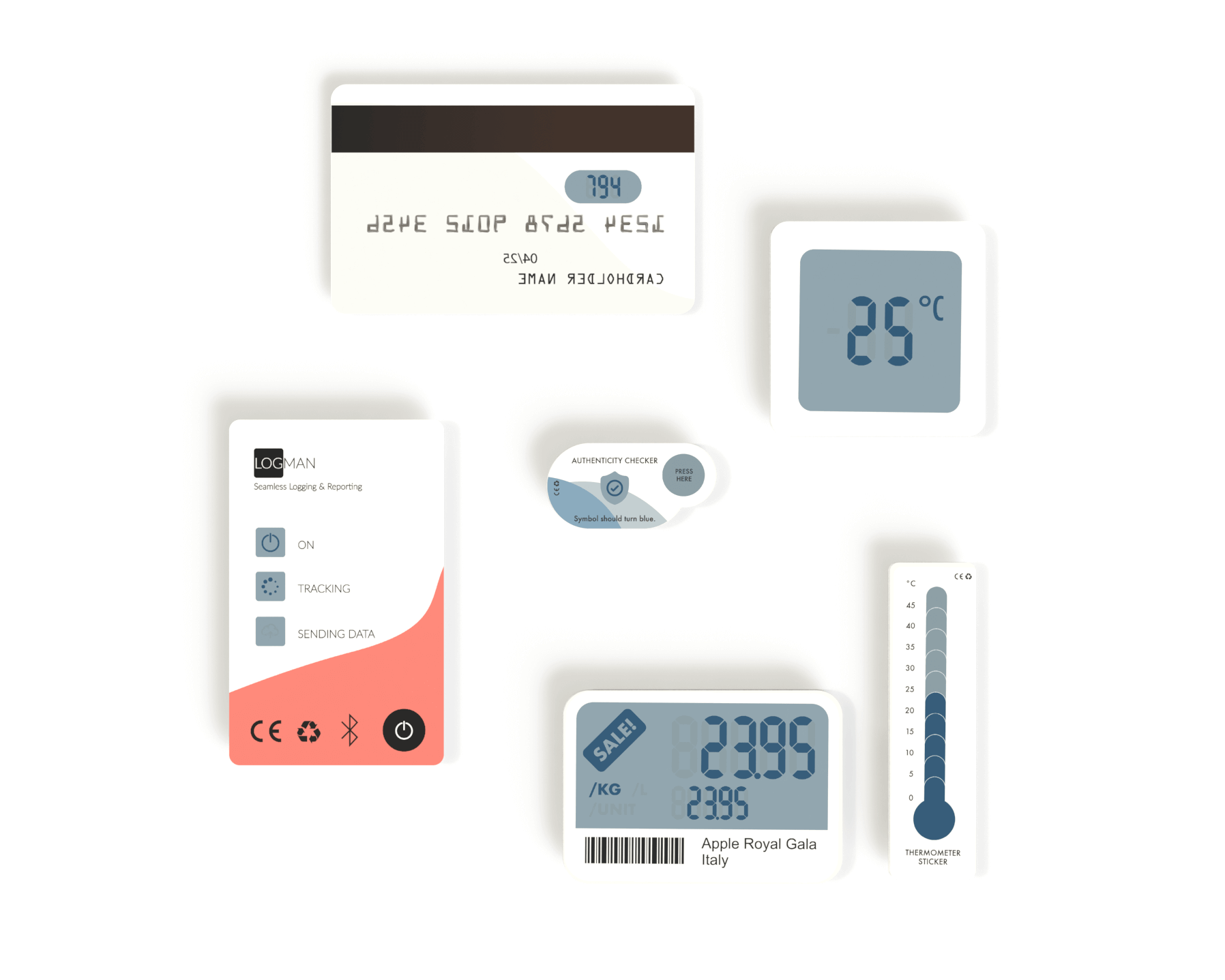

Endless Flexibility

Flexible Substrates

The displays are screen-printed on flexible plastic substrates.

Flexible Designs

Virtually all segments and symbols can be achieved in multiple colors. Graphic overlays are commonly used for a great look.

Flexible Manufacturing

Sheet-to-sheet printing for rapid prototyping with inexpensive tooling and setup. Multiple display varieties can be produced with the same tool set.

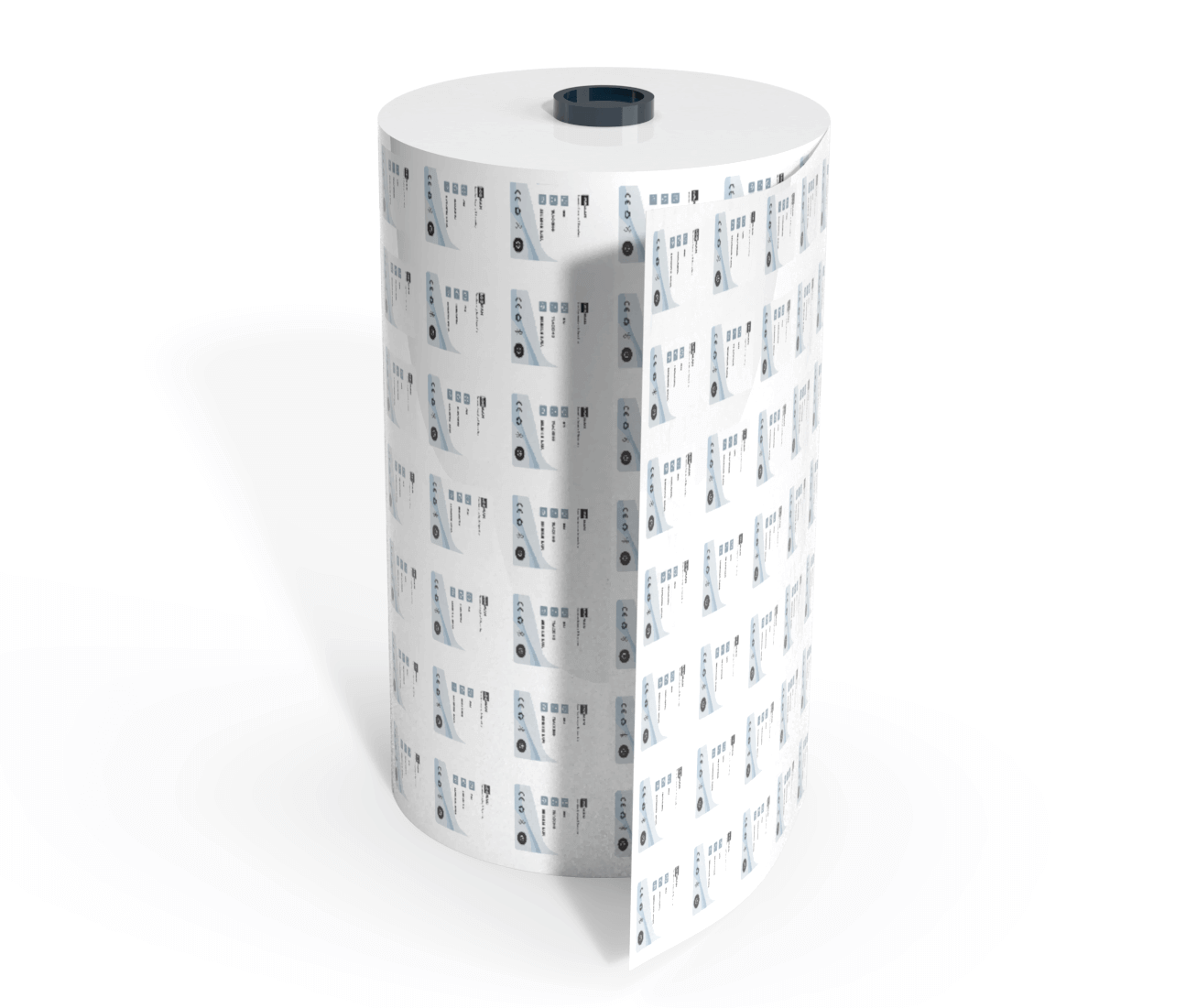

Screen Printing Production

The Rdot Display is manufactured using conventional and cost-effective printing processes. The production process is, in a wider sense, commonly referred as printed electronics. Both Sheet-to-Sheet (S2S) and Roll-to-Roll (R2R) production methods are available

Rapid Prototyping and Pilot Production

The in-house sheet-to-sheet production line is the preferred choice for rapid prototyping and custom design projects. The typical project lead time from sketch to delivered display is usually less than three months. The same S2S production line can be used for pilot production with capacity up to several thousand display units per month.

Mass Production

A roll-to-roll production method is the most cost-effective option for mass production. Rdot has a preferred manufacturing partner for mass production, but are also open for licensing if very large volumes are demanded. The cost per produced display area is dependent on factors such as expected volume, display footprint, and environmental requirements. Contact us with your project-specific details for cost estimations.